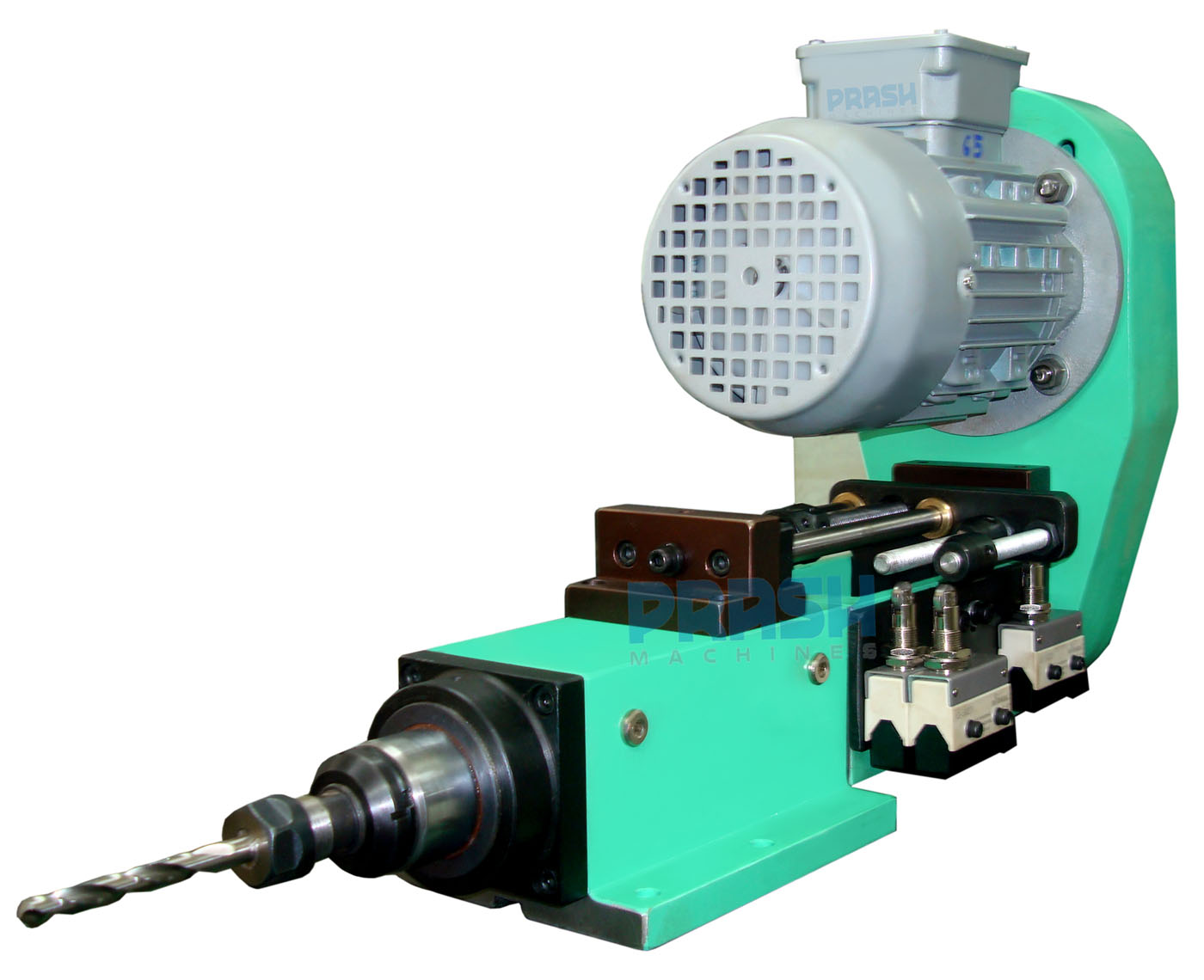

Drilling Head-Quill Type

Compact design

Economical

Available in Pneumatic & Hydraulic

High pneumatic rapid

Adjustable Rapid Forward-Feed-Rapid Return

Compact design

Economical

Available in Pneumatic & Hydraulic

High pneumatic rapid

Adjustable Rapid Forward-Feed-Rapid Return

See

Drilling Head-Quill Type products

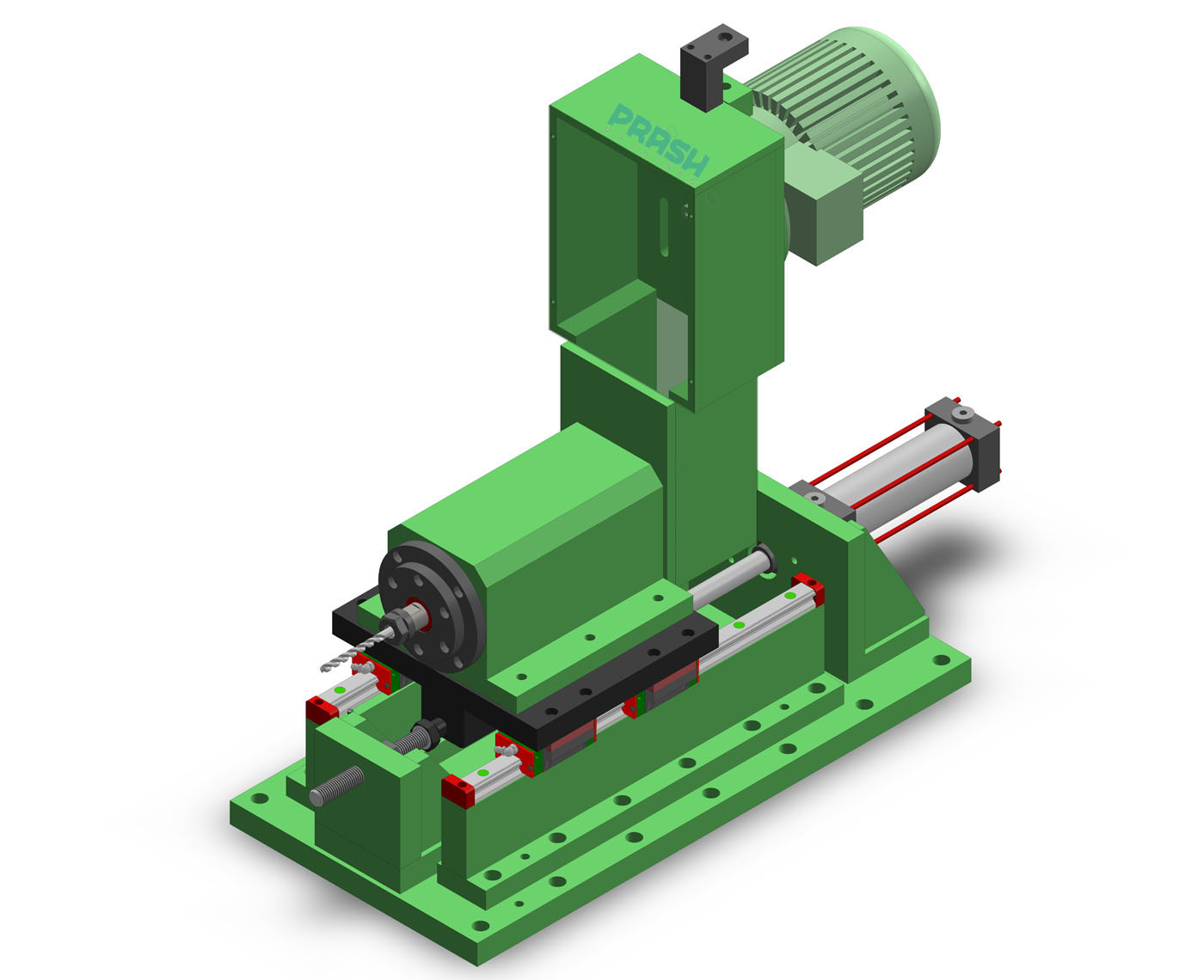

Drilling Head-Hydraulic Slide Type

Cartridge type Spindle design

Highly precise and robust Spindle

Non drifting Spindle

High thrust powerful drilling

Precise and rigid LM Guide Slide

Adjustable Rapid Forward-Feed-Rapid Return

Cartridge type Spindle design

Highly precise and robust Spindle

Non drifting Spindle

High thrust powerful drilling

Precise and rigid LM Guide Slide

Adjustable Rapid Forward-Feed-Rapid Return

See

Drilling Head-Hydraulic Slide Type products

Multi Spindle Drilling/ Tapping Head

Fix or Adjustable Center distances

Drill Length variation compensating Spindles

Silent running by Harden & Ground Gears

Radial Float & Length Compensation Spindles for Tapping

Customized Drilling capacity & Matrix

Suitable to be mounted on any drilling machine

Fix or Adjustable Center distances

Drill Length variation compensating Spindles

Silent running by Harden & Ground Gears

Radial Float & Length Compensation Spindles for Tapping

Customized Drilling capacity & Matrix

Suitable to be mounted on any drilling machine

See

Multi Spindle Drilling/ Tapping Head products

Drilling Machine-Quill Type

Compact design

Economical

Available in Pneumatic & Hydraulic

High pneumatic rapid

Adjustable Rapid Forward-Feed-Rapid Return

Compact design

Economical

Available in Pneumatic & Hydraulic

High pneumatic rapid

Adjustable Rapid Forward-Feed-Rapid Return

See

Drilling Machine-Quill Type products

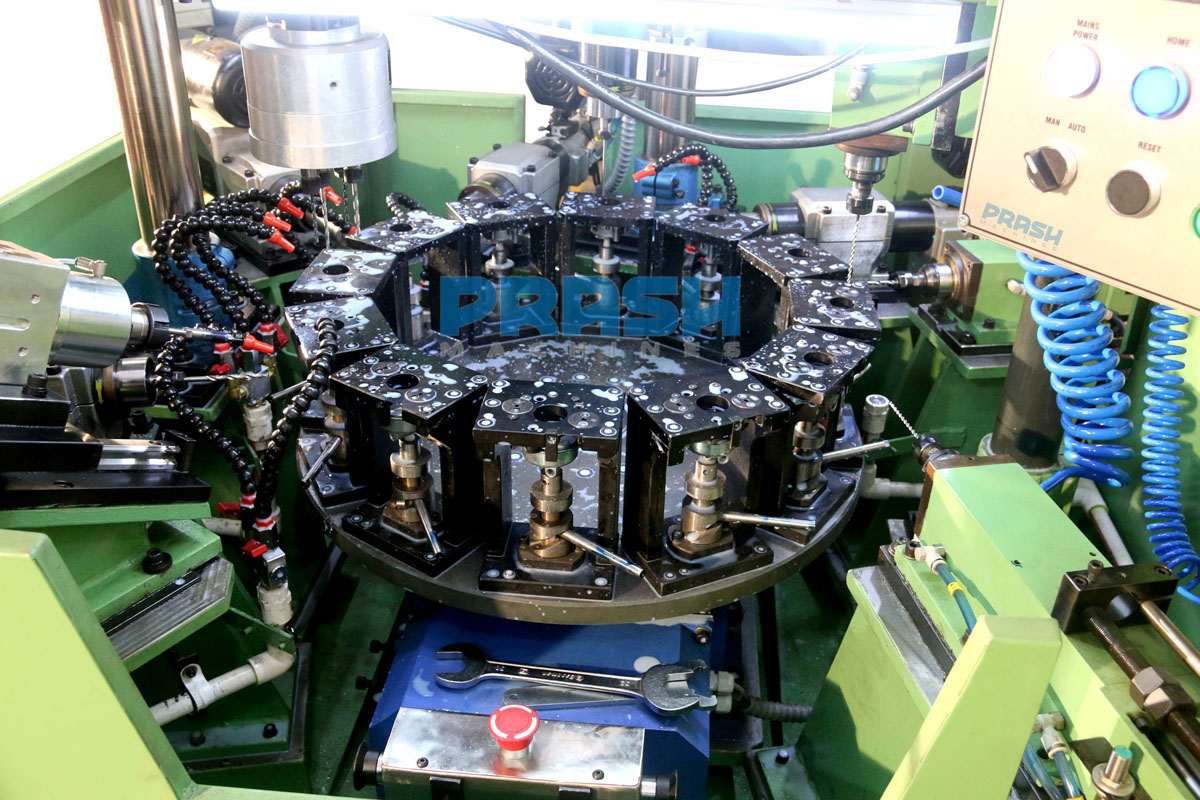

Twelve Station Rotary Indexing Drilling Tapping Reaming Machine

Multiple operation Drilling/Tapping/Reaming

Rotary Indexer with Hirth Coupling

Cam Type Fixture

Cam/Spring/Toggle Auto/manual part clamping

Manual/Auto Part Loading/Unloading

Bottom Bearing support for Index Top Plate

Auto recirculating coolant

Multiple operation Drilling/Tapping/Reaming

Rotary Indexer with Hirth Coupling

Cam Type Fixture

Cam/Spring/Toggle Auto/manual part clamping

Manual/Auto Part Loading/Unloading

Bottom Bearing support for Index Top Plate

Auto recirculating coolant

See

Twelve Station Rotary Indexing Drilling Tapping Reaming Machine products

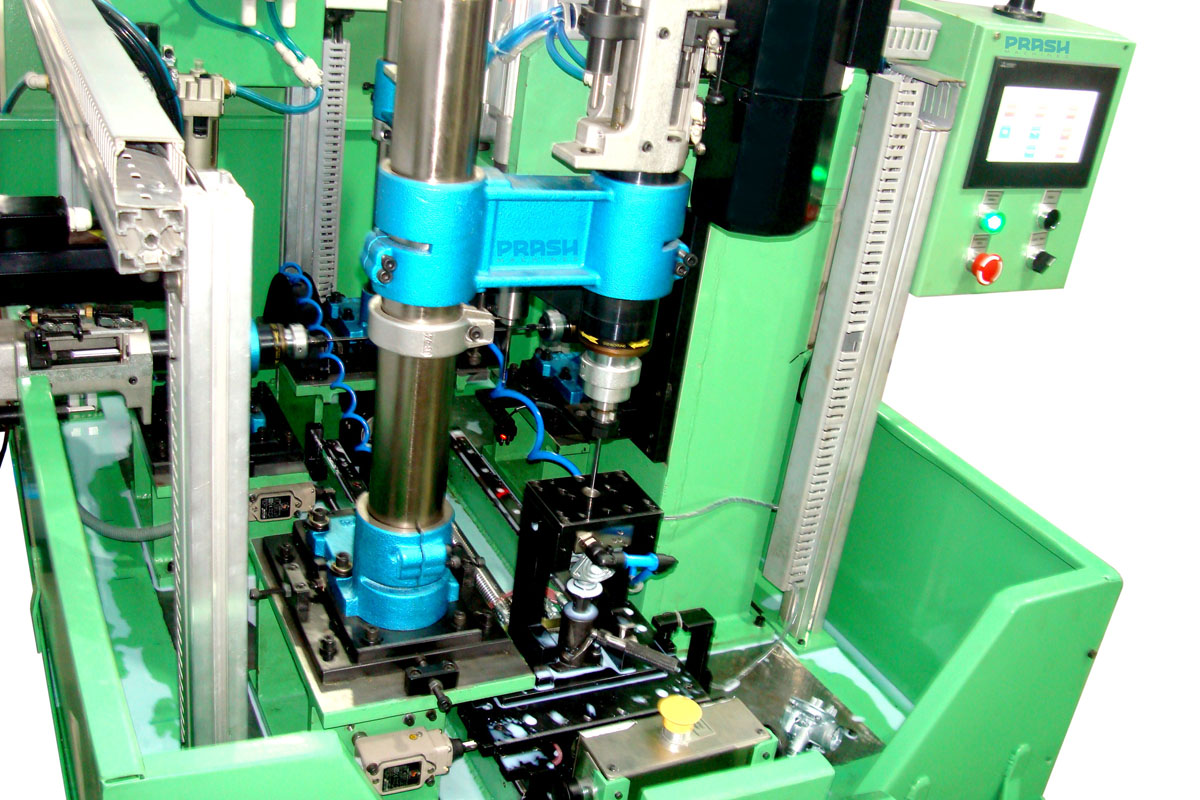

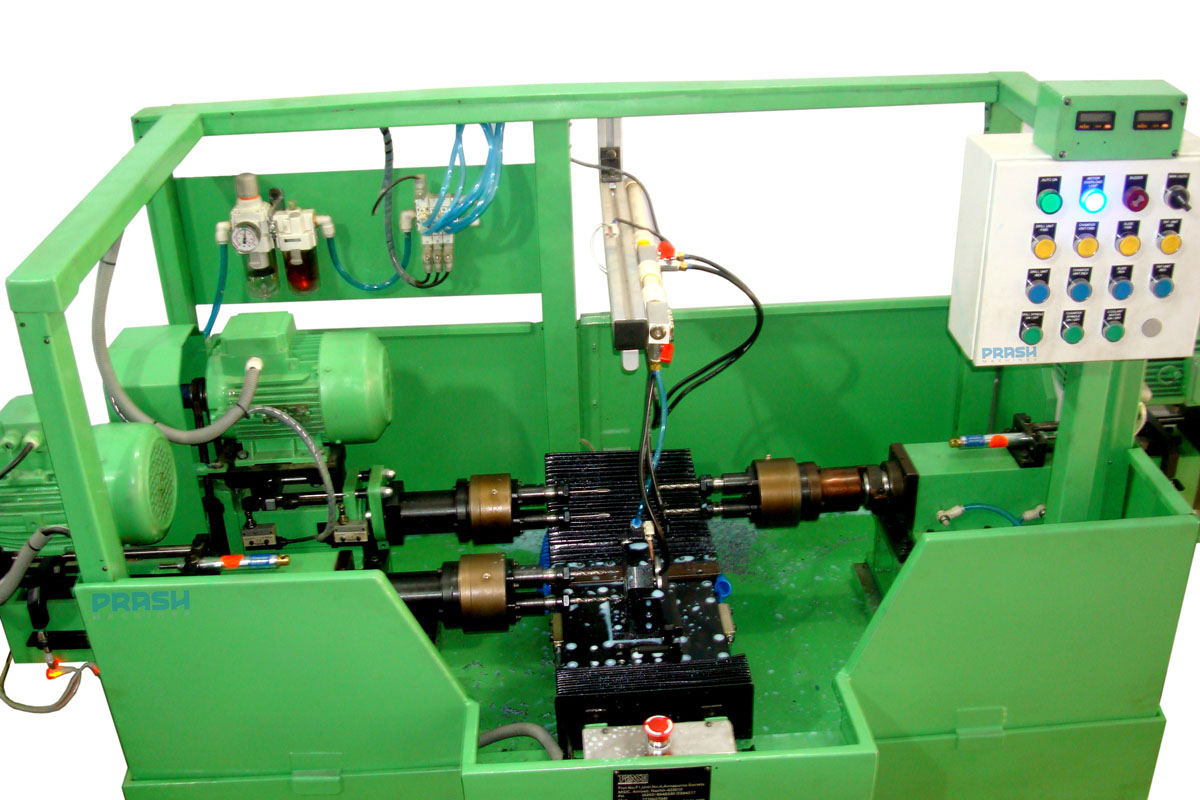

Linear Slide Drilling/Reaming Machine

Multiple operation Drilling/Reaming

Servo Slider with LM Guide ways

Cam Type Manual Part Clamping

Auto recirculating coolant

Auto Lubrication

Pneumatic High Speed Drilling Heads

Multiple operation Drilling/Reaming

Servo Slider with LM Guide ways

Cam Type Manual Part Clamping

Auto recirculating coolant

Auto Lubrication

Pneumatic High Speed Drilling Heads

See

Linear Slide Drilling/Reaming Machine products

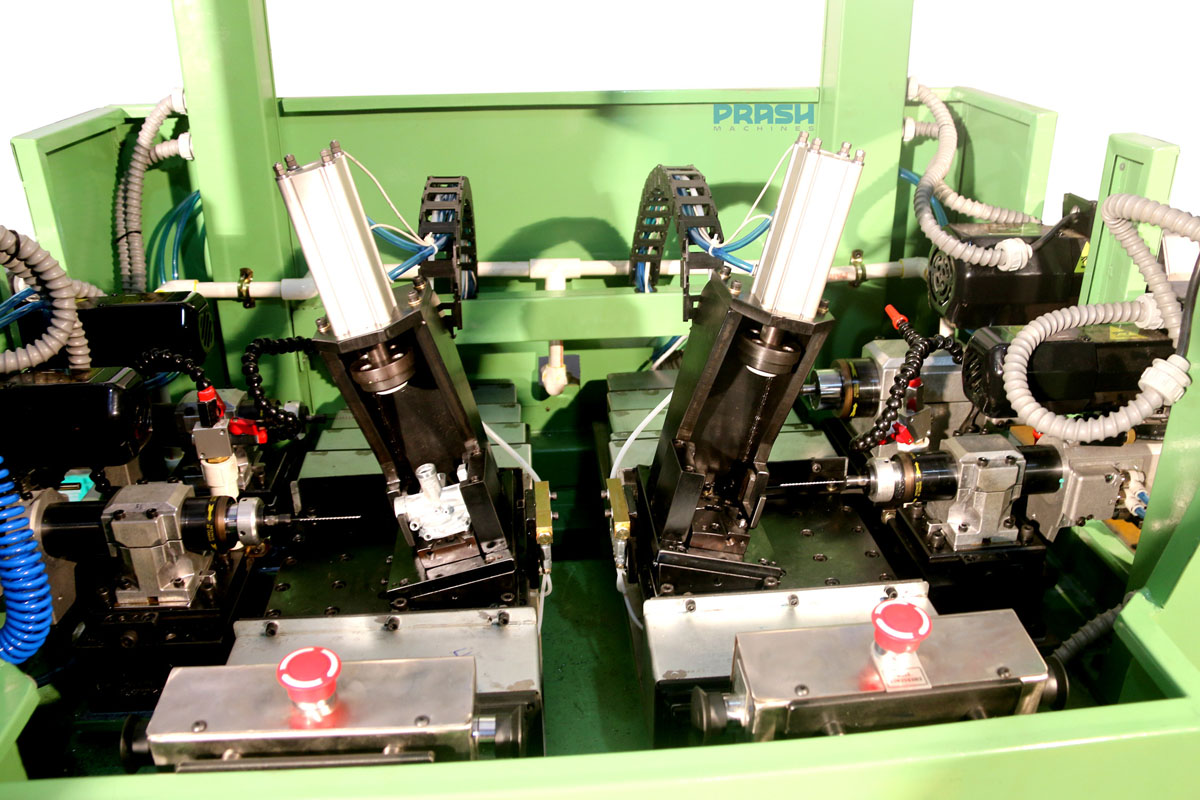

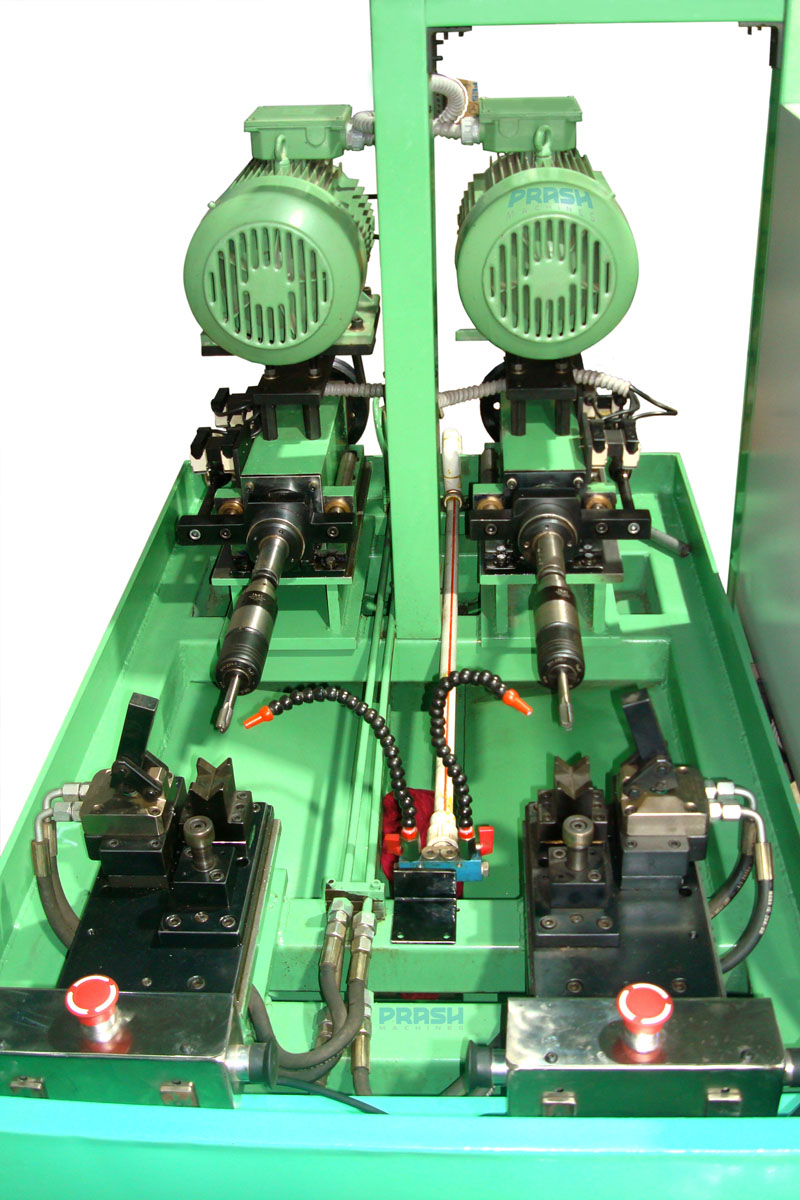

Two Slide Drilling Machine

Multiple operation Drilling

Independent Stations for more productivity

Pneumatic Part Clamping

Auto recirculating coolant

Auto Lubrication

Pneumatic Slide/LM Guide Ways

Multiple operation Drilling

Independent Stations for more productivity

Pneumatic Part Clamping

Auto recirculating coolant

Auto Lubrication

Pneumatic Slide/LM Guide Ways

See

Two Slide Drilling Machine products

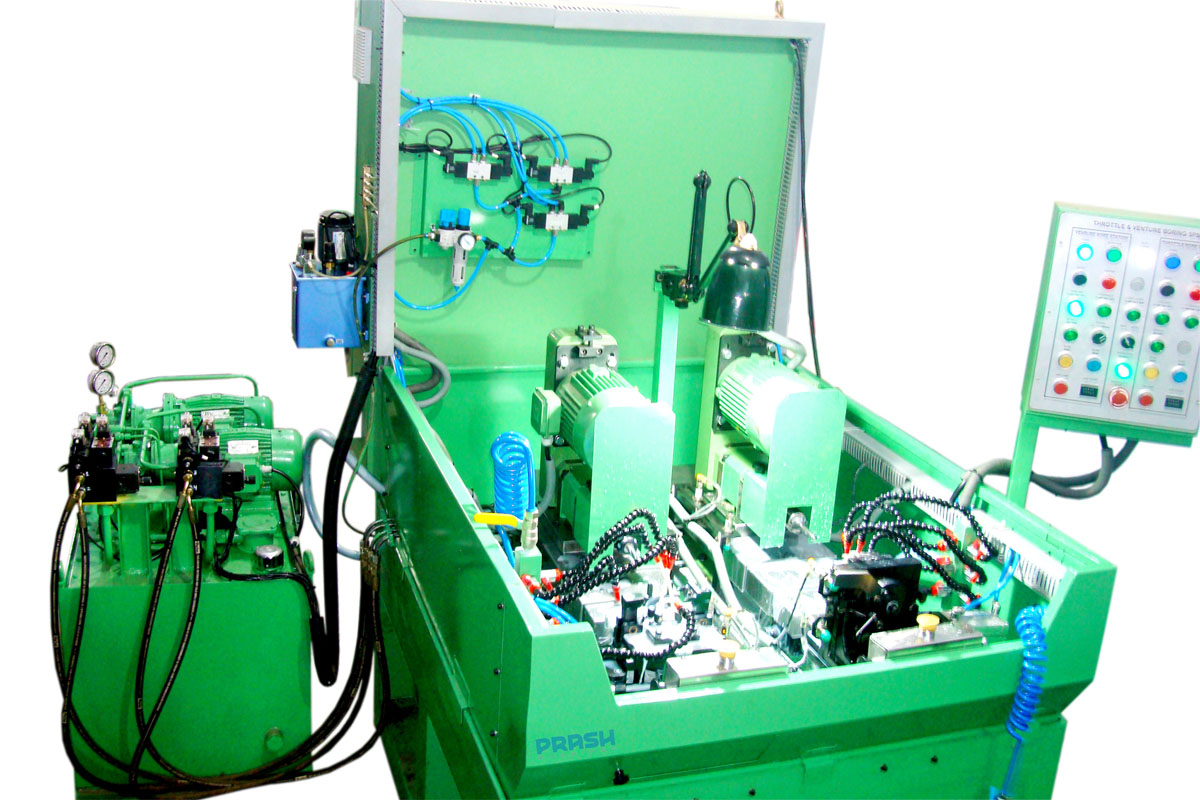

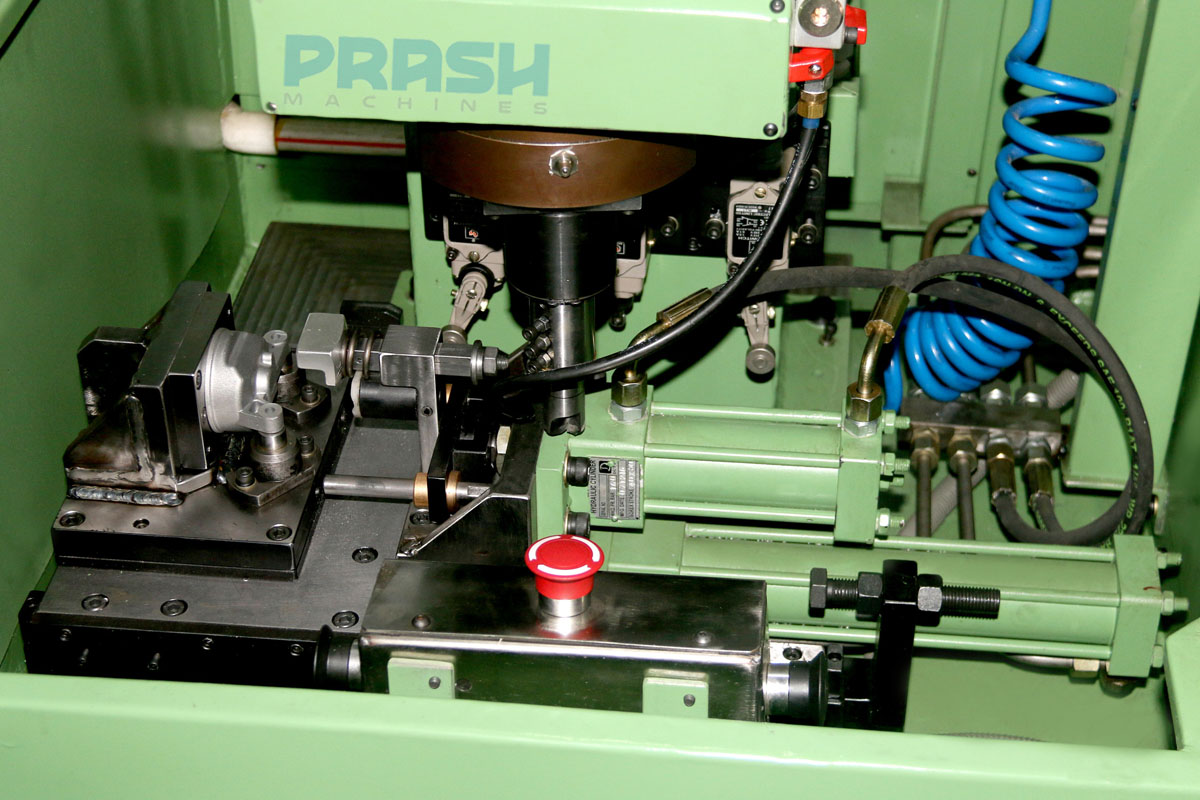

Multi Station Boring Machine

Milling/Boring/Reaming Heads

Hydraulic/Pneumatic/Servo Slide with Box Type Harden/LM Guide ways

Hydraulic/Pneumatic/Manual Part Clamping

Auto recirculating coolant

Auto Lubrication

Milling/Boring/Reaming Heads

Hydraulic/Pneumatic/Servo Slide with Box Type Harden/LM Guide ways

Hydraulic/Pneumatic/Manual Part Clamping

Auto recirculating coolant

Auto Lubrication

See

Multi Station Boring Machine products

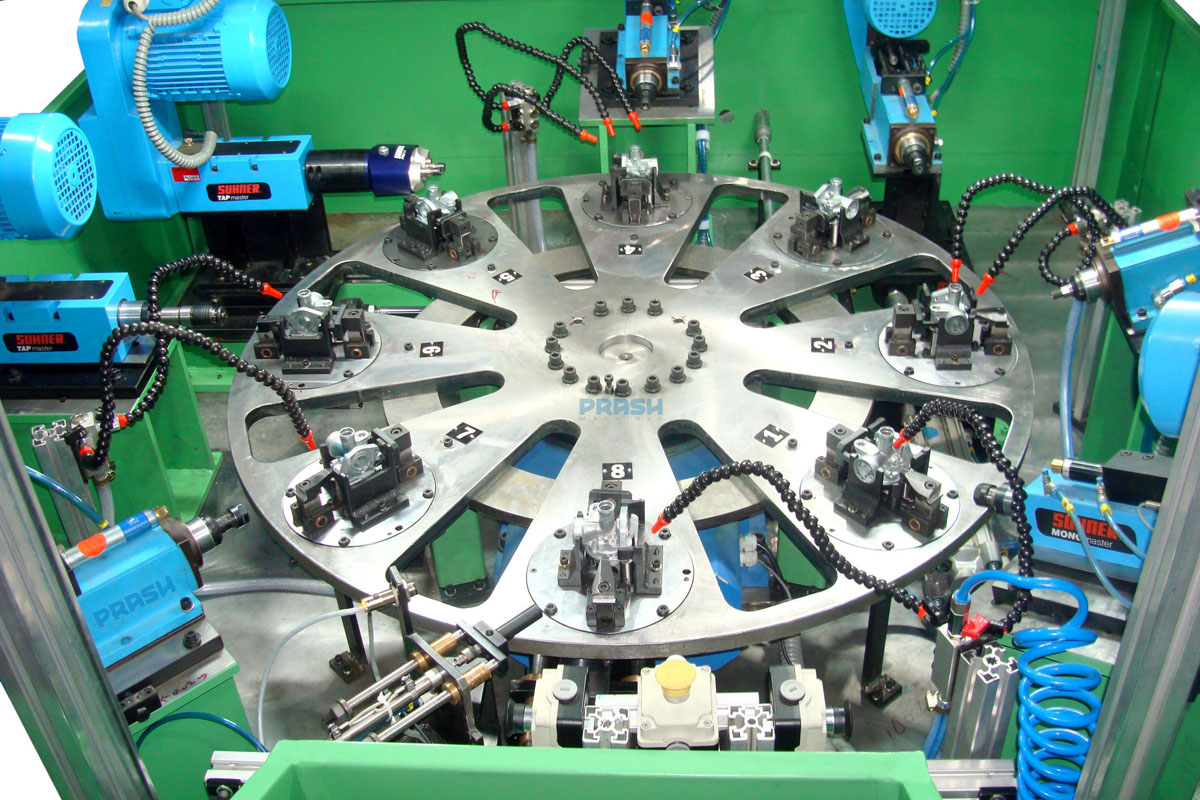

Eight Station Rotary Indexing Drilling Tapping Reaming Machine

Multiple operation Drilling/Tapping/Reaming

Rotary Indexer with Hirth Coupling

Fixture Auto Indexing

Multi Spindle Drilling

Auto recirculating coolant

Multiple operation Drilling/Tapping/Reaming

Rotary Indexer with Hirth Coupling

Fixture Auto Indexing

Multi Spindle Drilling

Auto recirculating coolant

See

Eight Station Rotary Indexing Drilling Tapping Reaming Machine products

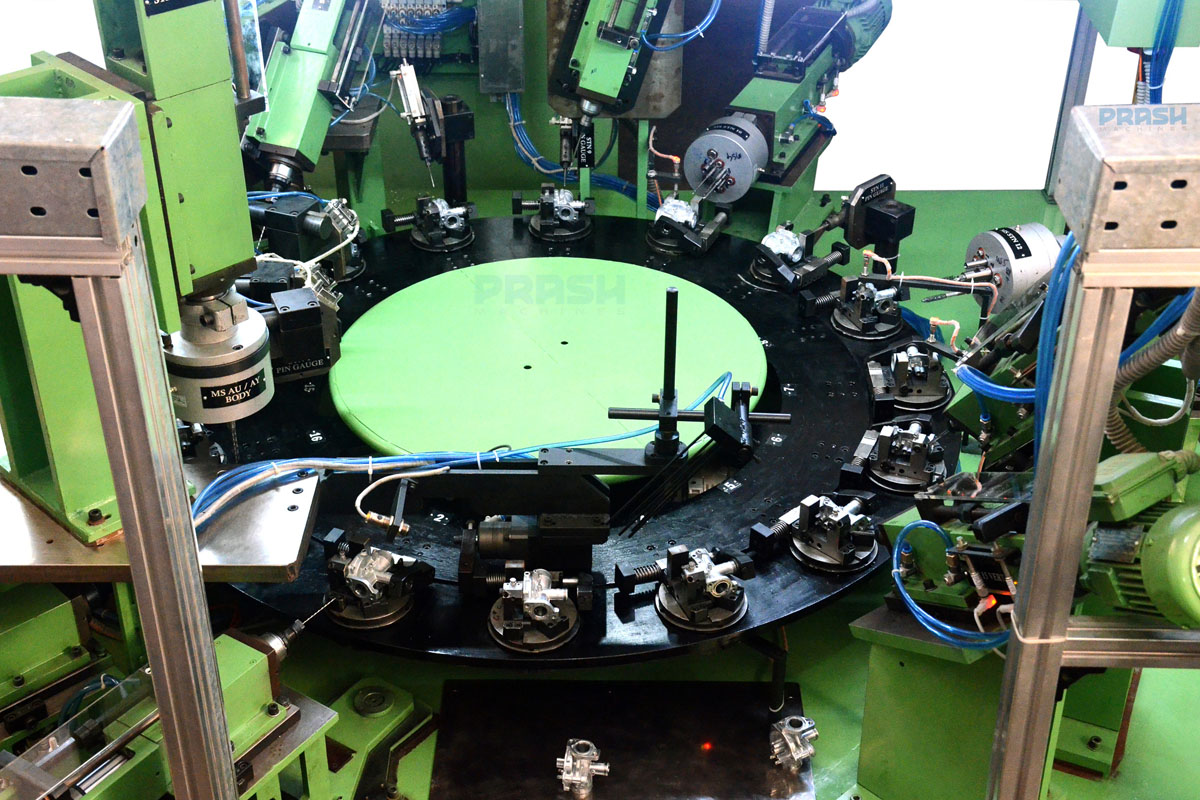

Sixteen Stations Rotary Indexing Machining Machine

Multiple Operations Drilling/Reaming/Chamfering

Rotary Indexer with Hirth Coupling

Auto Fixture Indexing

Multi Spindle Drilling/Reaming

Multiple Operations Drilling/Reaming/Chamfering

Rotary Indexer with Hirth Coupling

Auto Fixture Indexing

Multi Spindle Drilling/Reaming

See

Sixteen Stations Rotary Indexing Machining Machine products

Six Station Rotary Indexing Machining Machine

Auto recirculating coolant

Toggle Clamp Fixture

Multi Spindle Drilling/Tapping

Multiple operation Drilling/Tapping/Milling

Auto recirculating coolant

Toggle Clamp Fixture

Multi Spindle Drilling/Tapping

Multiple operation Drilling/Tapping/Milling

See

Six Station Rotary Indexing Machining Machine products

Multi Station Tapping Machine

Multi Station Tapping

Hydraulic Part Clamping

Auto recirculating coolant

Pitch Control Tapping

Multi Station Tapping

Hydraulic Part Clamping

Auto recirculating coolant

Pitch Control Tapping

See

Multi Station Tapping Machine products

Linear Slide Multi Spindle Milling Machine

Multi Spindle Milling

Linear Hydraulic Slide/ LM Guide Ways

Auto recirculating coolant

Hydraulic Part Clamping

Multi Spindle Milling

Linear Hydraulic Slide/ LM Guide Ways

Auto recirculating coolant

Hydraulic Part Clamping

See

Linear Slide Multi Spindle Milling Machine products

Linear Slide Drilling Machine

Linear Hydraulic Slide

Hydraulic Part Clamping

Auto recirculating coolant

Linear Hydraulic Slide

Hydraulic Part Clamping

Auto recirculating coolant

See

Linear Slide Drilling Machine products

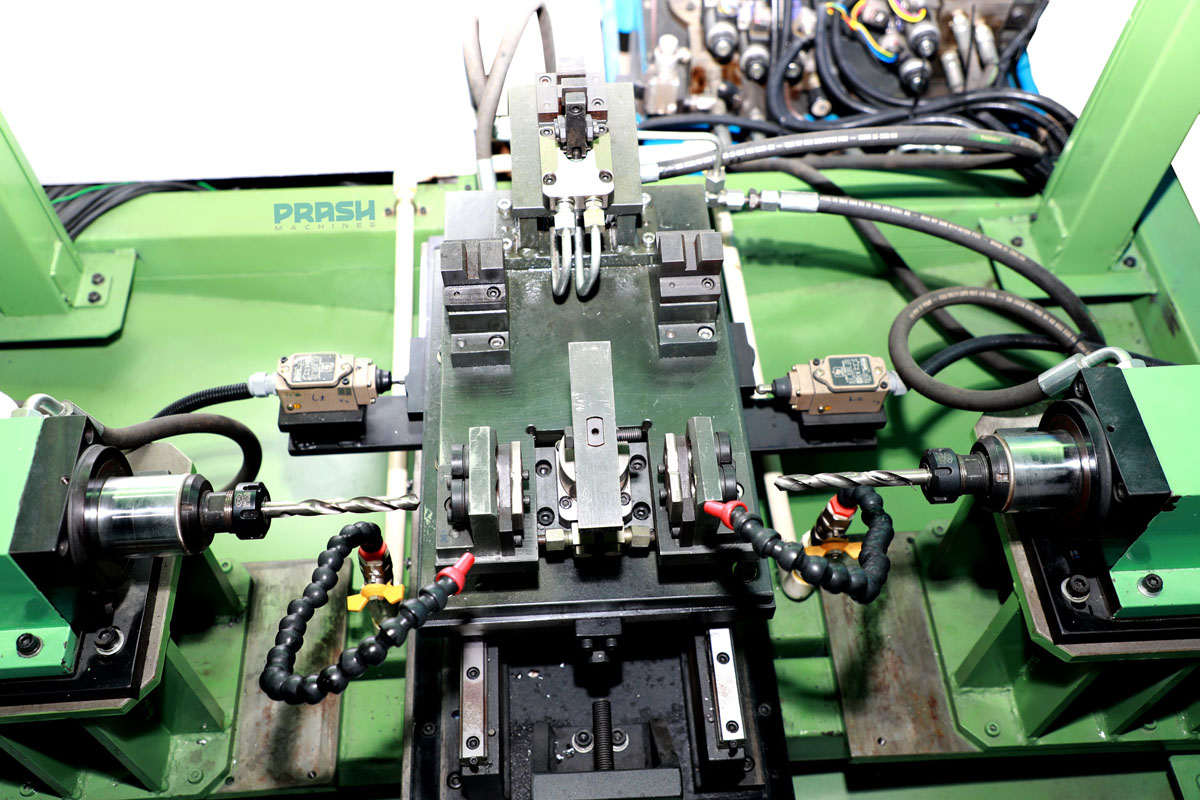

Linear Slide Multi Spindle Drilling/Chamfering/Tapping Machine

Multi Spindle Drilling/Chamfering/Tapping

Manual Clamping

Linear Pneumatic Slide/LM Guide Ways

Auto recirculating coolant

Multi Spindle Drilling/Chamfering/Tapping

Manual Clamping

Linear Pneumatic Slide/LM Guide Ways

Auto recirculating coolant

See

Linear Slide Multi Spindle Drilling/Chamfering/Tapping Machine products

Pitch Control Tapping Machine

Pitch Control Tapping

Pneumatic Part Clamping

Tap Breakage Warning

Hole Confirmation Sensor

LH/RH Part Variants Adjustment

Auto Tap Lubrication With Air Blow

Safety Light Curtains

Pitch Control Tapping

Pneumatic Part Clamping

Tap Breakage Warning

Hole Confirmation Sensor

LH/RH Part Variants Adjustment

Auto Tap Lubrication With Air Blow

Safety Light Curtains

See

Pitch Control Tapping Machine products

Multi Spindle Drilling Machine

Multi Spindle Drilling

Quill Type Drilling Head

Hydraulic Part Clamping

Multi Spindle Drilling

Quill Type Drilling Head

Hydraulic Part Clamping

See

Multi Spindle Drilling Machine products

PRASH MACHINES

We specialize in the development of one of the special purpose machining machines, that normally require integration of mechanics, fluid power and control as well as electrical/electronic systems. We incorporate full engineering concepts, computer aided designs, electrical and electronics, hydraulics, pneumatics control engineering, tooling, final assembly and testing.

PRASH MACHINES

We specialize in the development of one of the special purpose machining machines, that normally require integration of mechanics, fluid power and control as well as electrical/electronic systems. We incorporate full engineering concepts, computer aided designs, electrical and electronics, hydraulics, pneumatics control engineering, tooling, final assembly and testing.